Insights into our work

From LOCA, OCA and hybrid to air, gel and tail bonding: together with our customers, we select the ideal bonding process that meets their specific requirements. Our technologies are rounded off by fully automated pick-and-place, automated optical inspection, hotmelt and gap-filling processes, which enable us to realize tailor-made solutions. With the help of flexible production layouts and constantly optimized processes, we can react immediately to requests and adapt production individually. In order to maintain our high industry standards in the future, we are committed to continuously investing in our already highly developed technologies and systems.

At home in the world

With our global production sites in Germany, Poland and China, we make the wishes of our customers and their visions possible. From our technology flagship in Weikersheim, we export our innovations, processes and expertise to our international plants in order to offer the same DATA MODUL standards worldwide. In this way, we utilize our global production and logistics space paired with our expertise in manufacturing large-volume system solutions. In conjunction with our 2,000 m² ISO 7 and ISO 5 clean rooms, our primary goal is to manufacture to the highest industry standards.

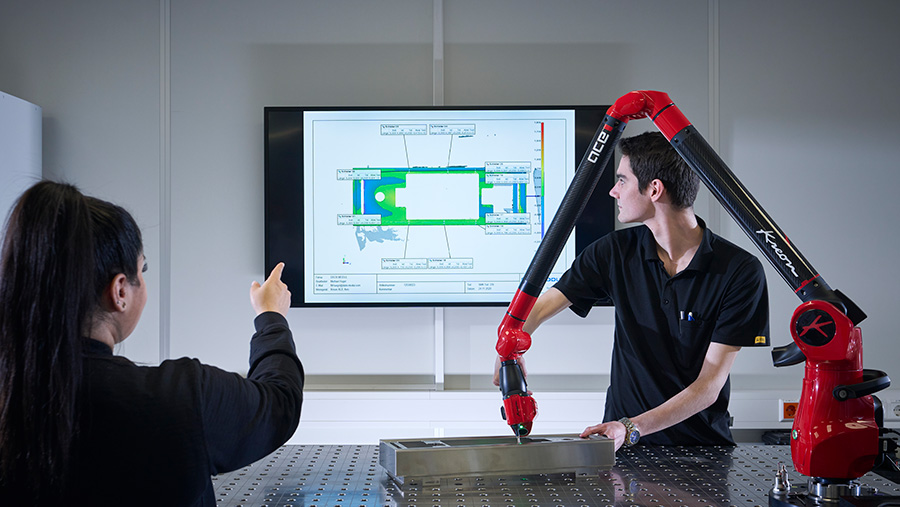

This is how we understand Quality Assurance

Our work is only successful when our customers are satisfied. Based on a global quality assurance strategy, we set standards in Europe for our production sites worldwide. Our aim is not only to ensure process conformity and quality transparency, but also to guarantee that our customers' quality requirements are met. In addition to standard certifications in accordance with ISO 9001 and ISO 14001, we also offer certification in accordance with ISO 13485.

Our Multiple Sourcing concept

To ensure successful production processes, we rely on a comprehensive multiple sourcing principle. By constantly monitoring the market, focusing on the entire supply chain and our long-term supplier sponsorships, our purchasing team adapts the procurement of components at short notice. This means that barrier-free production is always our top priority.