Optical bonding materials

LOCA / OCR

LOCA (Liquid Optically Clear Adhesive) is a liquid, optically transparent adhesive that we cure using UV light. This highly transparent adhesive is ideal for the precise bonding of rigid components such as TFT displays, touch sensors and cover glasses.

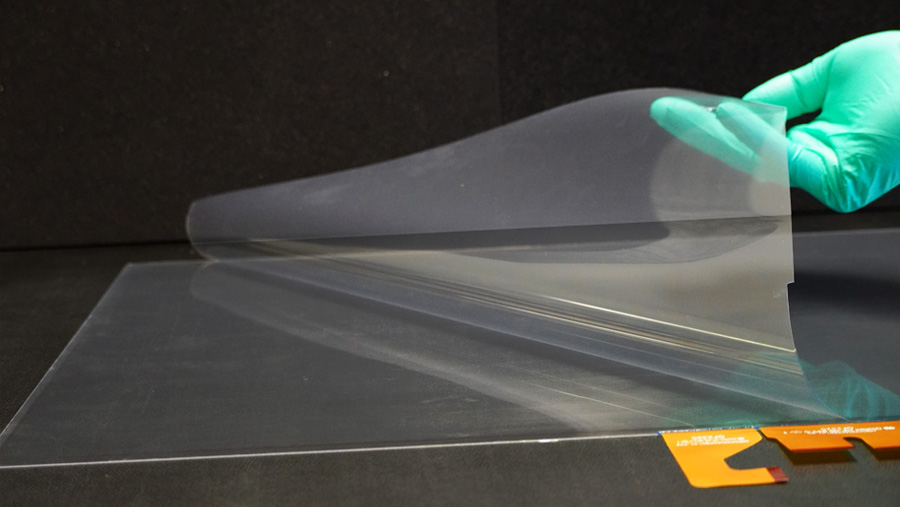

OCA

OCA (Optically Clear Adhesive) is a transparent adhesive coating that is used particularly in optical bonding lamination processes. This adhesive is suitable for bonding flexible and rigid components and is often used to bond FF sensors to cover glasses.

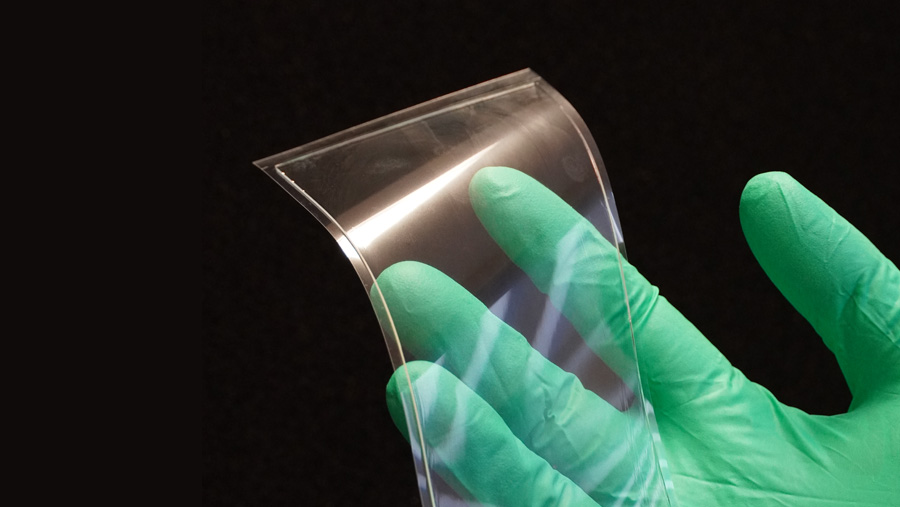

Gel

Gel is a flexible adhesive film that is ideal for the optical bonding of rigid components such as TFT displays and cover glasses. Thanks to its high flexibility, the gel adapts ideally to the surfaces and provides an even, transparent bond.

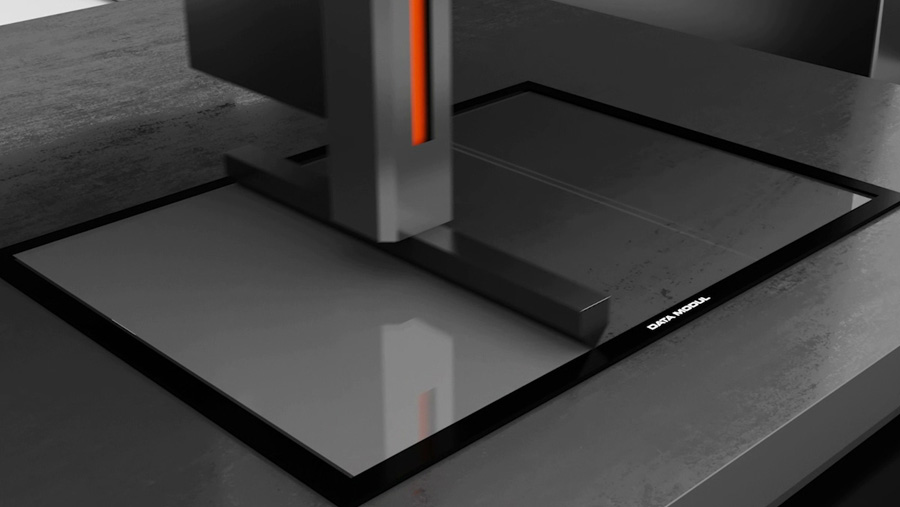

Optical bonding processes

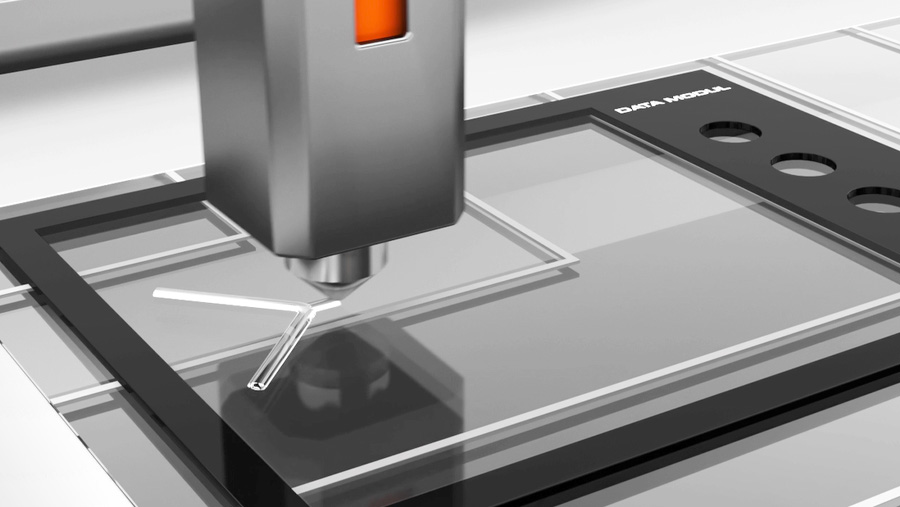

Dam & Fill

Dam & Fill is a precise process in which liquid adhesive is applied in a targeted manner to bond displays, touch and cover glasses. Curing takes place quickly and efficiently using UV light.

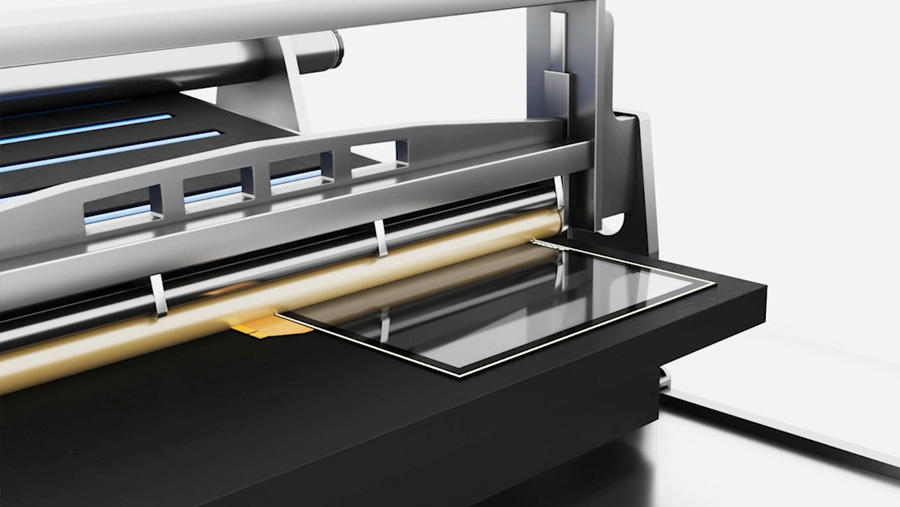

Lamination

Lamination combines flexible and rigid components using roll lamination and an autoclave process. An OCA coating ensures a homogeneous and stable optical bond.

Hybrid optical bonding

Hybrid optical bonding combines the advantages of LOCA and gel in a cost-efficient process. The slit coating process enables precise adhesive application, ideal for high-volume touch solutions.

E-field

E-field is an innovative process in the field of optical bonding for cost-effective touch solutions on a large scale. It uses an electric field to control the bonding process of cover glasses and displays.

Industry solutions for optical bonding

Innovative display solutions with optical bonding for a wide range of industries: our customised displays are used wherever maximum readability, robustness and reliability are required under demanding conditions. Whether industrial HMI, food industry or smart buildings: optical bonding ensures that displays remain clear, high-contrast and durable even in challenging environments.

Industrial HMI

In industrial HMI, optical bonding ensures better readability, even in bright ambient light, dusty conditions or vibrations. The fixed connection between the display and touch unit also increases robustness and resistance to mechanical stress – a decisive advantage in CNC machines, conveyor systems or robot controls, for example.

Food industry

Hygiene and safety are crucial for applications in food production. Displays with optical bonding prevent condensation and facilitate cleaning while maintaining image quality. This allows production lines, packaging machines and monitoring systems to be controlled reliably.

Industrial Automotive & EV charging

In the automotive sector and at EV charging stations, optical bonding ensures that displays remain easy to read even in direct sunlight, high temperatures or humidity. The additional robustness protects against shocks and vandalism, thus contributing to a longer service life for the systems.

Smart Building & White Goods

For smart building solutions or household appliances (e.g. refrigerators), optical bonding ensures high-contrast, durable displays that remain easy to read in all lighting conditions. At the same time, the strong bond protects the display from moisture, dust and dirt, thus supporting compliance with the respective protection class.