We understand your requirements in the laboratory environment

In demanding hygienic environments, the products used must fulfil essential requirements. Particularly in the field of laboratory diagnostics, the highest quality standards are essential - from in-vitro diagnostics (IVDR/FDA) to IEC 61010 and ISO 13485. In addition, the products must be extremely robust to ensure comprehensive protection against contamination. They must be resistant to harsh cleaning agents to ensure functionality and ensure that components are not damaged by aggressive substances. Furthermore, there must be no false triggering, for example due to unintentional touch events such as water or blood on the display, in order to guarantee reliable use and precise diagnostics.

Let us realise your product vision!

We understand the challenges in laboratory technology and fulfil all the necessary certifications to ensure safety and hygiene in the development and production of medical operating devices. In this way, we guarantee maximum process reliability and precise results.

Robust components for laboratories and clinical environments

Our products are designed to withstand the high demands of laboratories and clinical environments. They are resistant to liquids, chemicals and other potentially harmful substances. The Hyclean TEC glass and the special antimicrobial surface coating not only contribute to sterility, but also protect against external influences that could affect the service life of the devices.

Certifications and conformity guarantee safety and quality

We fulfil all relevant certifications, including In-Vitro Diagnostics (IVDR/FDA), IEC 61010 and ISO 13485, ensuring not only the quality of our products, but also compliance with international standards for medical devices. Our strict adherence to these standards ensures that the devices can be used reliably and safely in demanding environments.

Versatile interaction options for precise operability

The precise operability of our products is ensured by various interaction options. PCAP sensors enable operation even when wearing gloves, which is essential in environments with strict hygiene regulations. The integration of gesture control and voice control enables touchless interaction, which is particularly advantageous in situations where physical contact should be avoided.

Realise your project together with us!

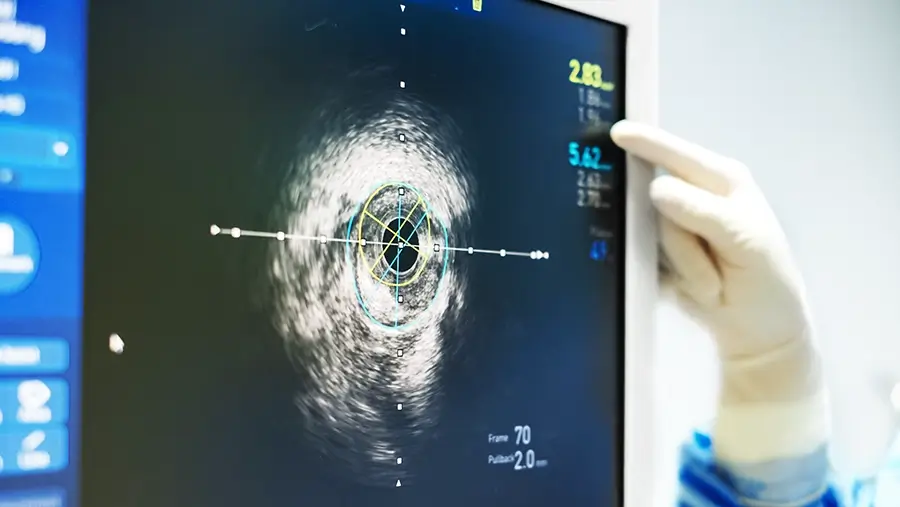

Ultrasound display systems

Medical analysis systems

Microscope solutions

Downloads

Precise adaptation to the specific requirements of the laboratory environment

Systems of the highest quality and performance are essential for applications in laboratory diagnostics. All components must not only be perfectly harmonised, but also function reliably as a complete system. In our modular product concept, we combine all of our company's technology areas into a well thought-out system. With state-of-the-art display technologies, the latest embedded boards and controllers, innovative touch extensions, efficient manufacturing processes and a wide range of housing variants, we offer our customers customised solutions from a single source.

Interested? Don't hesitate to contact us!

Do you have any questions?

Give us a call!

+49 89 56017 0*

*Our hotline is open Monday to Friday from 8 a.m. to 5 p.m. Costs according to your tariff for calls to the German landline.